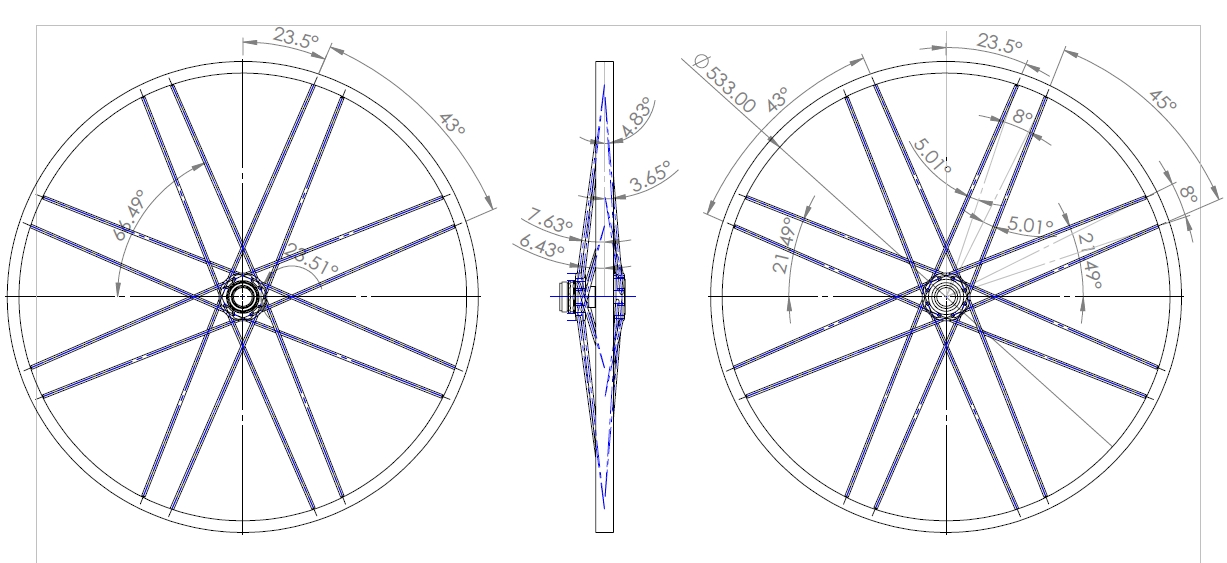

WHEEL SYSTEM DEVELOPMENT

Core Values

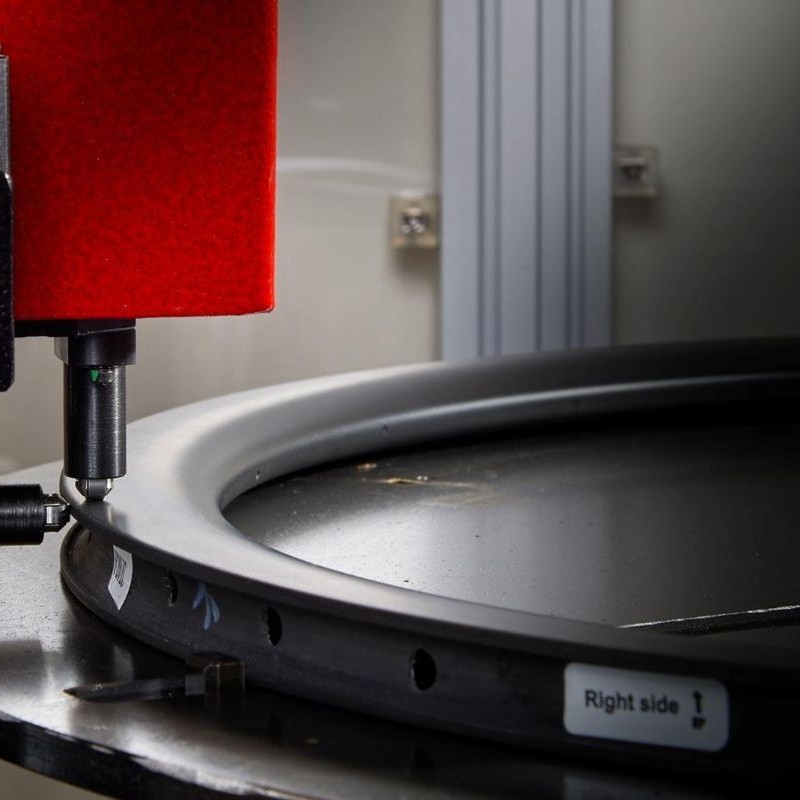

PROCESS of WHEEL SYSTEM DEVELOPMENT:

|

|

|

|

Customer Benefits:

- Design Cycle Reduction: Eliminate prototyping phases

- Market Responsive Production : Launch products faster

- Risk Mitigation: All engineering validations complete

Value-Added Services:

- Replacement Kits: Simplify inventory with our cross-brand compatible parts

- Technical Support: We provide complete product launch documentation

- Demand-Driven Manufacturing: Low MOQ

Product Inquiry

| Image | Product Name |

|---|---|

|

WHEEL SYSTEM DEVELOPMENT |